UTECH Las Americas is the most important event in Latin America dedicated exclusively to the polyurethane industry, a sector that has registered significant growth in recent years and points to positive perspectives for the future. The fair returns to Mexico City from June 13 to 15, 2023.

As in the last edition, Amino will be present at the event with innovations in raw materials for the world of comfort in flexible foams, with emphasis on surfactant silicones, amine catalysts, liquid organic pigments and special additives. Viscoelastic, hyper soft and flexible high resilience systems will also be presented.

Discover the latest trends and solutions in the industry and keep up to date with the main technologies that Amino offers to the market at the biggest event in the Latin American polyurethane industry.

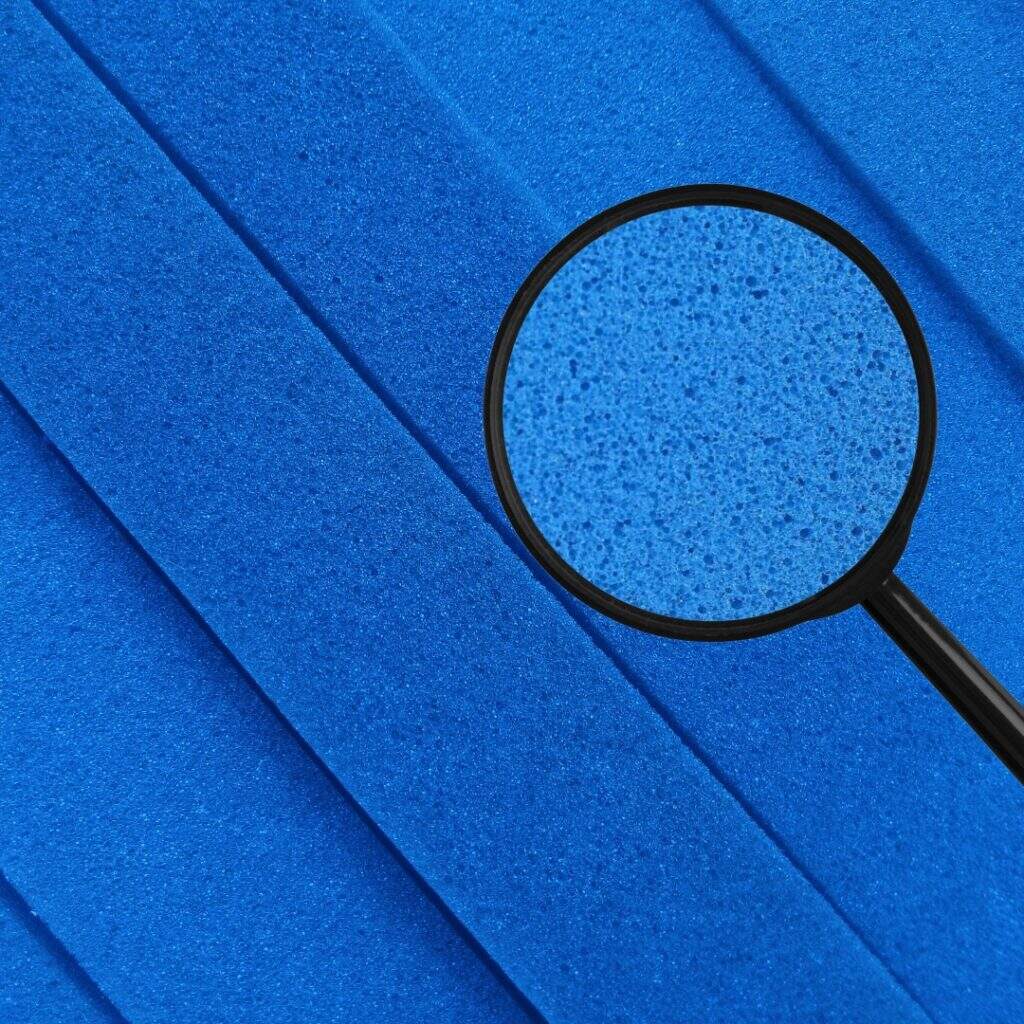

Surfactant Silicones

Despite representing a small portion of the formulation, silicone is important to ensure the interaction of all components at the time of reaction, producing uniform, small and open cells, and a more homogeneous distribution of density in the foam. Amino produces and markets a complete line of high-performance silicones under the AMISIL brand and develops customized solutions according to the customer’s needs.

Amine Catalysts

Amine catalysts are popularly known as foam reaction promoters, but their polymerization and expansion characteristics must be well used to offer and provide the best performance to the final product. Amino produces its trademark AMICAT, with balanced formulations suited to each customer’s process needs.

Pigments

Amino presents AMICOLOR to the market, a complete line of liquid organic pigments with high dyeing power, dispersed in the base polyol of the foam. In addition to the traditional colors used by the market, Amino also develops special colors according to customer standards.

Memory Foam System

High degree of comfort, low resilience and slow return. The characteristics of viscoelastic foams can vary according to different needs. Amino presents the Visco Elastic Pneumatic All MDI systems, ecological 100% water-based, for discontinuous, continuous and molded block processes.

Hyper Soft System

The hyper soft foam has great softness and touch sensitivity as its main characteristics. Following all international technical requirements, Amino has the most advanced technology to supply discontinuous, continuous and molded rectangular and cylindrical process systems.

High Resilience System

Foam with excellent support characteristics and fast return. The systems developed by Amino rely on technology that includes discontinuous, continuous and molded block processes, with better skin finishing and less deformation.

Adhesives

Amino has the most advanced technology for the production of adhesives with the AMIPRE line. With low viscosity, without odor and emission of volatiles, controlled reaction according to the customer’s needs, good hardness, high resistance to tearing and bonding power on different substrates.

Special Additives

Flexible foams are extremely versatile and can be designed for different applications. To ensure the best performance for the purpose of each foam and meet the specific standards of each sector, Amino has the largest mix of special additives on the market, from adhesion promoters to additives for stretching and tearing.

About Amino Química

Amino is a reference in formulations and development of PU raw materials. We serve the largest manufacturers in Brazil and South America with a modern plant with high installed production capacity for the entire global market. We are the chemical industry with the greatest mix of polyurethane applications, specializing in surfactant silicones, amine catalysts, liquid organic pigments, special additives, PU systems for various sectors and the most advanced technology in the CASE line (Coatings, Adhesives, Sealants, Elastomers ). We have a team of expert technicians to analyze, guide and develop exclusive solutions to offer the best customer experience.