PU Systems and Adhesives that help your company

We serve a variety of Polyurethane applications for the footwear industry, in the processes: molded and block.

Amino Polyurethane

Why is Polyurethane such an important component in the shoe and insole industry?

Polyurethane, more commonly known in the market as PU, is often used in the footwear market, more specifically in soles, midsoles, and insoles because it offers numerous positive properties:

- Withstands high light exposure

- Very flexible

- Has good shock absorption properties

- It is highly resistant to abrasion

- Has good anti-slip properties

Polyurethane Solutions

Talk to AminoLab engineers

We have developed PU technology that adheres to the various standards of the shoe industry.

Technology and Innovation

Polyurethane is one of the most efficient and versatile polymers for footwear manufacturing

Amino’s system was developed on the basis of polyether polyol for use in the manufacture of sports, safety and casual footwear. Our insole presents great flexibility, with a soft and comfortable touch, providing a better final footwear. Our sole system, on the other hand, has high hydrolysis resistance and performance. For each type of specification there is a suitable insole and, consequently, the best component or combination of them to meet the requirement. There are many materials that can compose an insole:

- Chemically expanded polyethylene

- Physically expanded polyethylene

- Antibacterial and Antifungal Polyethylene

- Production of leather insoles

- Fabric Insole Production

- Eva Perforated

- High-density PU foam

- Molded and unmolded Latex insoles

- Felt insoles

Scientific knowledge and passion for innovation in the refrigeration industry

Amino is constantly evolving. Our mission is to expand the possibilities of design, safety, performance, comfort, reliability, and sustainability.

Polyurethane insole system

Polyurethane sole system

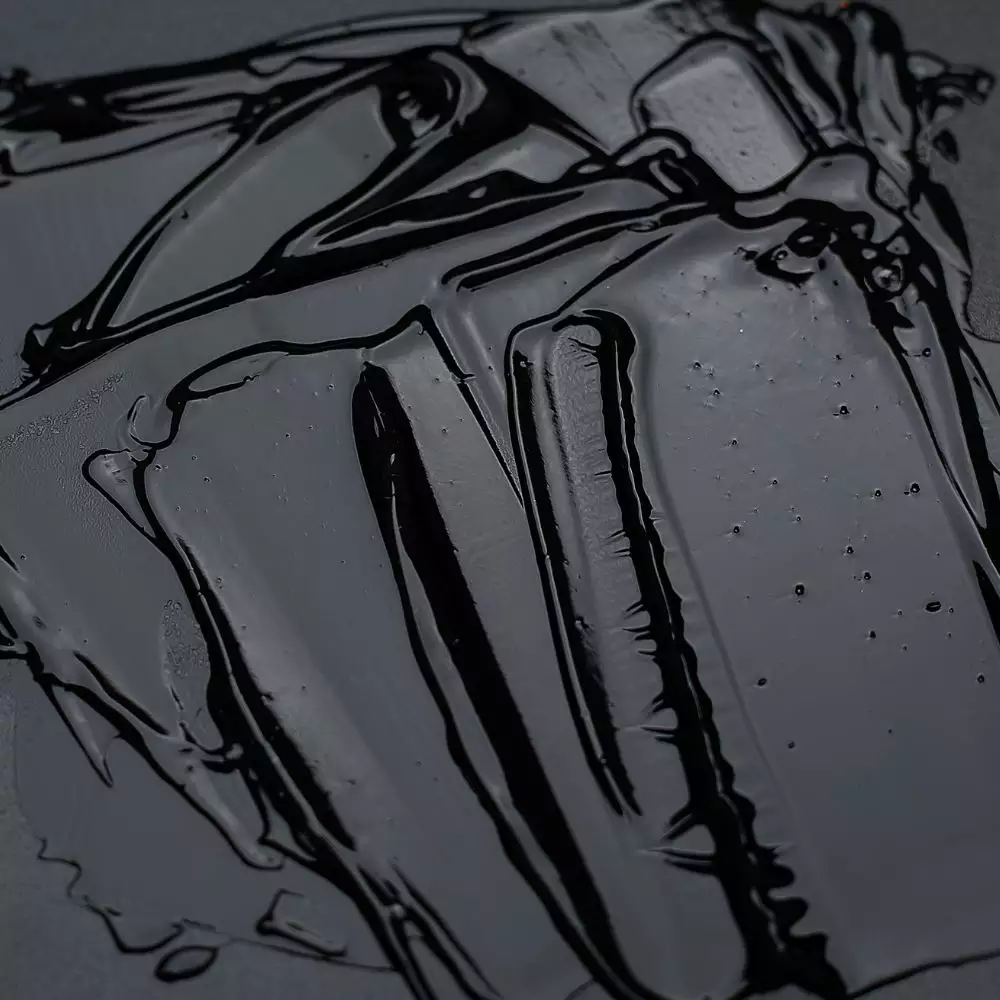

Black pigment for sole

Plastisol for soles and labels