For the Polyurethane and Plastisol Markets, Amino Develops Solutions Aimed at Meeting Customer Expectations and Ensuring Excellence in Product Quality and Final Application

With a focus on Technological Innovation and Sustainability, Amino maintains a robust infrastructure for research, testing, development, trials, and qualified laboratory analyses, many of which comply with standards set by Inmetro, ABNT, and other regulatory bodies.

Learn More About Our Laboratory Infrastructure

To cater to the diverse needs of the Polyurethane and Plastisol markets, we provide an extensive structure divided into:

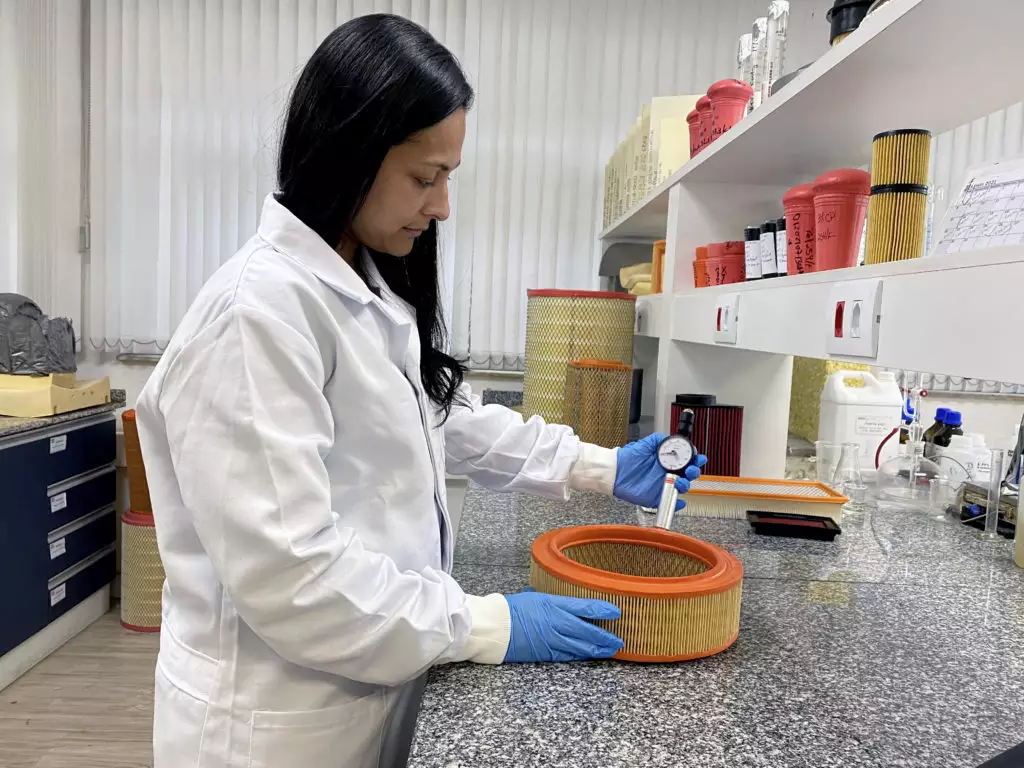

- Chemical Laboratory: For product research, development, and quality control.

- Physical Laboratory: For conducting tests in compliance with various standards.

- Pilot Unit: For training our clients on new technologies to be implemented in their businesses.

What Amino’s Laboratories Offer

- Extensive Infrastructure: Equipped for advanced analysis and testing.

- Quality Analyses and Product Testing: Ensuring compliance with national and international standards.

- Technical Support: Expertise in various polyurethane and plastisol segments.

- Broad Scope: Analysis of different products across diverse segments, ensuring alignment with regulations from leading authorities.

Check out the article: “Foam Quality Testing: Why Is It So Important?” [Click Here]

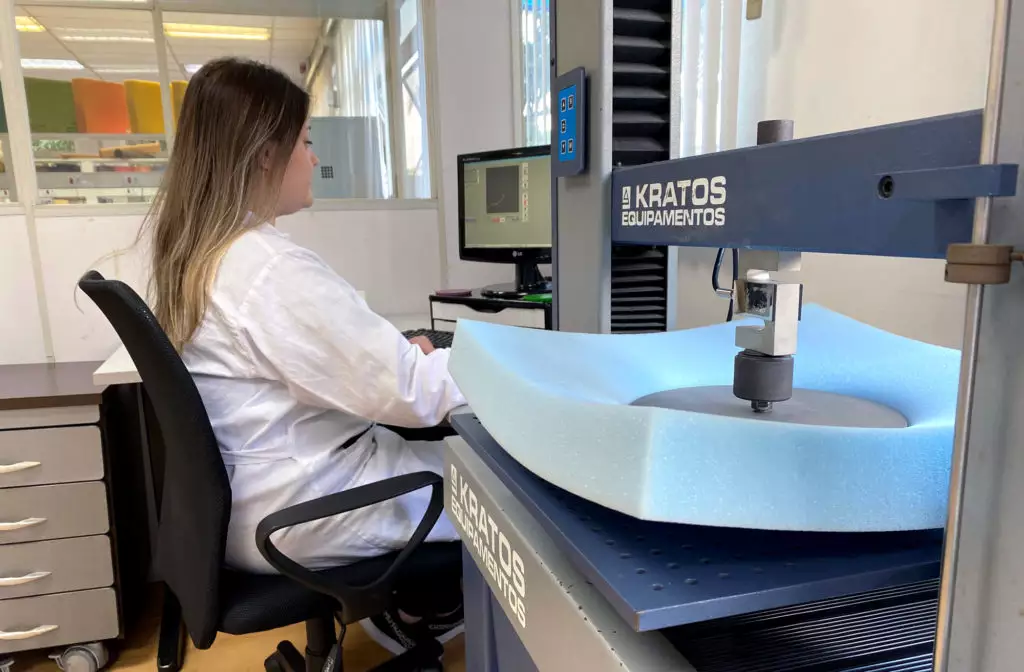

Tensile Strength and Elongation Testing – ABNT NBR 8615

Tensile or rupture strength of flexible foam is the ratio between the force required to break it and the dimensions of the sample, expressed in kPa. Elongation, in turn, measures the foam’s stretch until rupture, expressed as a percentage (%).

Tear Resistance Testing – ABNT NBR 8616

This test measures the tear resistance in N/m offered by a foam sample when subjected to tensile force. It serves as a parameter to evaluate the foam’s suitability for applications where it may be exposed to shear and tensile conditions.

The test involves applying a tensile force to a standardized cut sample.

For more information about Amino Technology, contact us at +55 11 4077-3777 or send an email to vendas@amino.com.br.

About Amino

Flexible PU foams play a fundamental role in various industries, and choosing the right system and additives is crucial to achieving the desired performance. If you want to learn more about how to optimize your production processes and explore Amino’s complete line of additives and solutions, contact us. We are ready to help you find the best solutions for your production needs!